The practice of introducing risk-based electromagnetic compatibility (EMC) and electromagnetic (EM) resilience for managing safety-related risks.

There is an ongoing trend to rely on electronics more and more for safety-related or -critical functions. This emerging area of electronics is socially one of the most sensitive as a failure of a critical safety feature can lead to drastic consequences, including loss of human life. To ensure that only safe products can enter and exist on the market, standardization sets specific requirements for operation, which different government entities enforce. These requirements provide the level of reasonable expectations for the equipment users and, at the same time, the minimum level of product performance for manufacturers. To help the society’s success on a mission for safer electronic products the “Pan-European Training, research and education network on ElectroMagnetic Risk management” (PETER) aims to provide new knowledge in the area of EMI Risk Management with a significant contribution to improve the state-of-the-art methods.

From the cloud of philosophy to a theory to rule

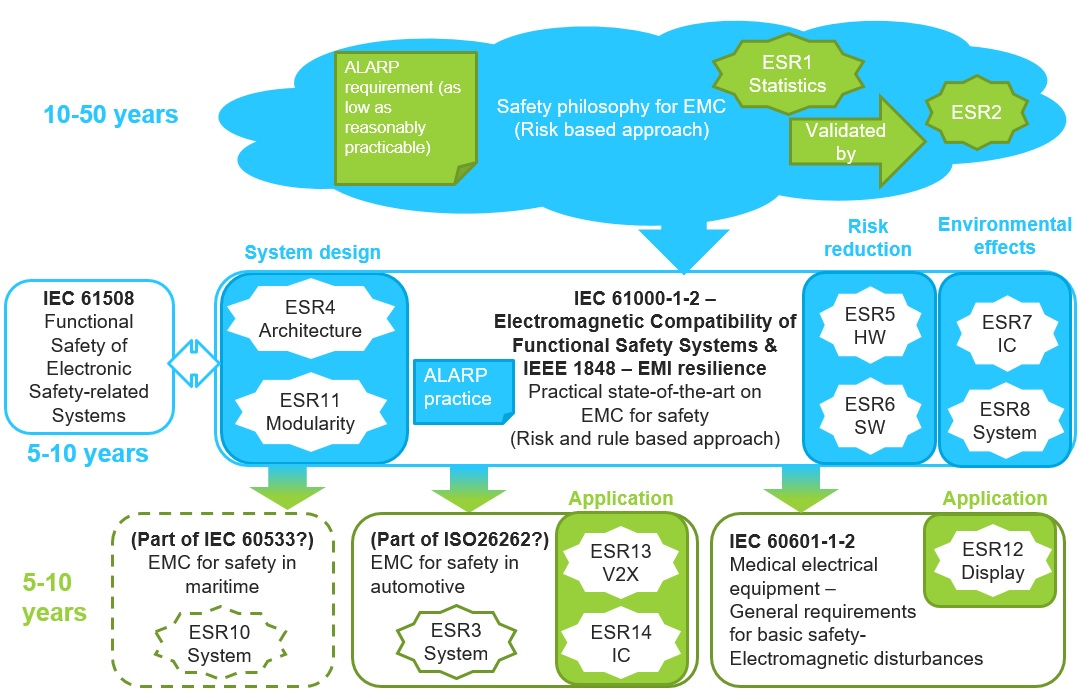

To provide a consistent background for standardization, there has to be a fundamental theoretical basis that it can rely on. Consistent background here means that the theory will hold for the next ten to fifty years. To persist for such a time, the field of theory needs to be well established, researched, peer-reviewed and widely accepted.

For the development of systems that possibly bear safety risks, a good starting point is the requirement called ALARP, which means that any risk needs to be as low as reasonably practicable. While ALARP is a term that is typically used in the UK, similar concepts exist in other countries as well (e.g. ALARA in the USA, EU Directive 89/391/EEC), and the same philosophy is followed over the whole world. As a requirement, it is widely accepted within the field without being too specific. The idea is that additional risk-reduction should be implemented into the system up to the level that the cost of any further reducing risk is grossly disproportionate to the value of the lives thereby saved.

As EMI can lead to significant safety risks, fundamental knowledge on the electromagnetic compatibility needs to append the safety theorem. This includes the simple and more complex laws of physics like Ohms law and Maxwell’s equations as well as much more complicated tools and techniques.

In the case of PETER, the fundamental knowledge extension happens by ESR1 doing research on statistical methods for EMC risk management and ESR2 verifying that research in practice. As it is with all very fundamental theories – one does not want to get them wrong. Hence, here the PETER project puts a lot of effort on in-depth review, not only relying on the rest of the scientific community, but also arranging cross-verification by the two ESRs.

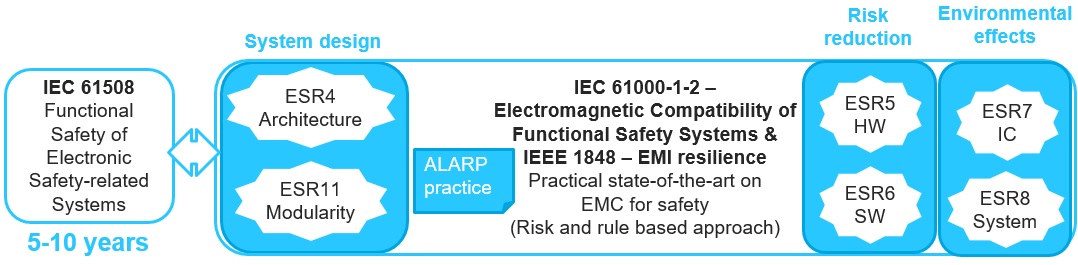

The standardization level

The Electromagnetic Compatibility of Functional Safety Systems standard (IEC 61000-1-2) should describe the practical state-of-the-art of its scope. It complements the General Functional Safety Standard of Electronic Safety-related Systems (IEC 61508) and needs to consist of a combination of risk- and rule-based approaches. A risk-based approach ensures that the philosophical ALARP requirement is implemented in practice. However, engineers work more efficiently with a defined set of rules. That is why the standardization needs to derive rules from the risk-based approach. These rules define the state-of-the-art in risk reduction. Currently, IEC 61000-1-2 lacks on this development and a new international standard on EMI resilience (IEEE 1848) leads the progress by providing a distinct set of rules. This is a good example that to keep up with the state-of-the art, this and any levels below need to follow the technological development as close as possible. That is why the expected update interval for the standards on these levels is 5-10 years.

Majority of the PETER project’s deliverables are on this level thus advancing the practical state-of-the-art to support engineering practice and standardization development. Related to system design, ESR4 concentrates on the system architecture and ESR11 on the system modularity. ESRs 5 and 6 will develop risk reduction techniques for hardware and software respectively. ESRs 7 and 8 will develop methods to take into account the environmental and ageing effects during the system lifetime. ESR7 will concentrate on integrated circuit (IC) level and ESR8 on system level effects.

Industry applications in PETER

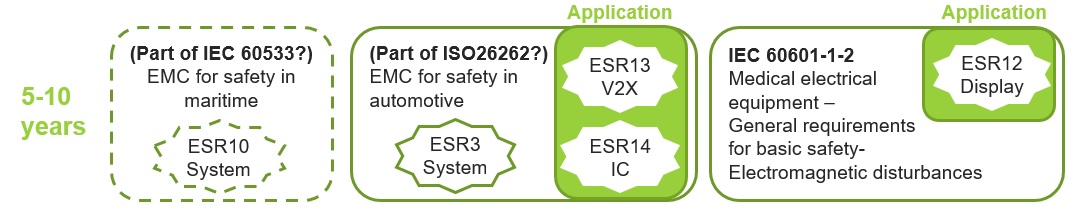

PETER will cover three main industry applications that have emerging safety needs: marine, automotive, and medical industries. Both marine and automotive sectors are moving towards autonomous navigation with the automotive sector leading the way. In the medical sector, the increased life expectancy of people and rising healthcare costs drive for more technological innovation to help to ease the healthcare staff workload. This innovation often comes in the form of electronic products.

For maritime environment, managing safety-risks of electronic products has concentrated on very specific use cases like fire safety and reduction of flooding during hull damage. General functional safety and especially EMI risk management are emerging topics with not much of concrete standardization – marine radio communication being an exception. The safety philosophy for marine environment comes from the International Convention for the Safety of Life at Sea (SOLAS). That is derived to the current rule-based approach of the marine EMC topics in the IEC 60533 standard, which is a reference publication for the marine classification societies imposing derived requirements based on the ship class they are certifying.

The marine area is shown as dashed for safety-related EMI risk management topics, as the ESR10 will mainly concentrate on specific topics outside safety: introducing a risk-based approach to generic marine EMC and some key marine-specific technical areas like common-mode voltage management. However, these methods have significance on the EMI risk management for safety and thus the dotted line is justified. It is recognized that the initial push given by this project needs to continue later in different projects.

For automotive environment, ESR3 concentrates on system level improvement of the EMC aspects in road vehicles functional safety standard (ISO26262). ESR3’s topics include improved architectures and use of computational methods. ESR3 uses the general work of ESR4 on architectural topics and work of ESR11 on modularity to achieve efficient reuse strategies that fit the automotive applications.

ESR13 and ESR14 concentrate on applications within automotive area. Namely, ESR13 covers the vehicle-to-X (V2X) communications that include at least vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I). ESR14 concentrates on topics related to the automotive use of integrated circuits (ICs). These both have significant safety implications, as the future of the autonomous vehicles is heavily reliant on success of modern integrated circuits and communication systems.

For medical electrical equipment, ESR12 concentrates on the specific application of medical displays, where the research focus is on application and improvement of Basic Safety Standard of Medical Electromagnetic Compatibility (IEC 60601-2). ESR12 will ensure that the current standardisation provides enough guidance for the whole product lifecycle and will propose any improvements, when appropriate.

PETER does not provide the standards updates – the international community does it!

The results of PETER research activity will provide a paradigm change in the area of managing safety risks due to EMI. However, this is just the first push for the standardization activity by having an adequate scientific background available. It will be the responsibility of the standardization community to implement them. Fortunately, PETER project senior staff has members with long experience on standardization to help and convey the message to the right places. They are also able to mentor some of the ESRs on an important role of technical expert responsible for writing the standard updates. With the good support of senior scientists, eager young minds and well-thought teamwork in the project, all of this will be possible!

About the Author: Oskari Leppäaho

Oskari Leppäaho accomplished his Master’s Degree in Electromagnetism at the Tampere University of Technology in Finland, 2015. Before joining the PETER project, he spent several years serving the industry on the fields of electromagnetic compatibility and electronics system design.

Oskari Leppäaho accomplished his Master’s Degree in Electromagnetism at the Tampere University of Technology in Finland, 2015. Before joining the PETER project, he spent several years serving the industry on the fields of electromagnetic compatibility and electronics system design.